Rompetrol added to its core downstream activities of refining and distribution of products the expertise of our traders located in Switzerland, our base of operations for international trading, and in Romania, the Group has developed efficient logistic assets that transform the country into an energy hub and gateway to Europe.

The diversity of supply sources is a key element of energy security, and the Group’s offshore marine terminal has a significant contribution to ensuring alternative feedstock supply routes, bringing the crude oil from Tengiz and Kashagan oilfields, the most resourceful areas of Kazakhstan.

Sustainability in Trading & Supply Chain

Minimizing the impact of the raw materials supply and product delivery activities is an important business objective for the Group.

Rompetrol is the largest exporter of petroleum products, gasoline, diesel, and the largest local producer of aviation fuel. Thanks to investments in refining units, these products meet Euro 5 quality standards.

The 700+ vessels unloaded a total volume of about 60.2 million tons of crude oil, intended exclusively to supply the largest refinery in Romania.

The crude oil brought in between 2009 and 2024 was mainly of Kazakh origin, as a result of the constant efforts made by the trading division of KMG International (Rompetrol). Incidentally, ship number 700 unloaded 80,000 tons of Kazakh KEBCO (Kazakh Export Blend Crude Oil), an assortment with increasing demand in the European Union.

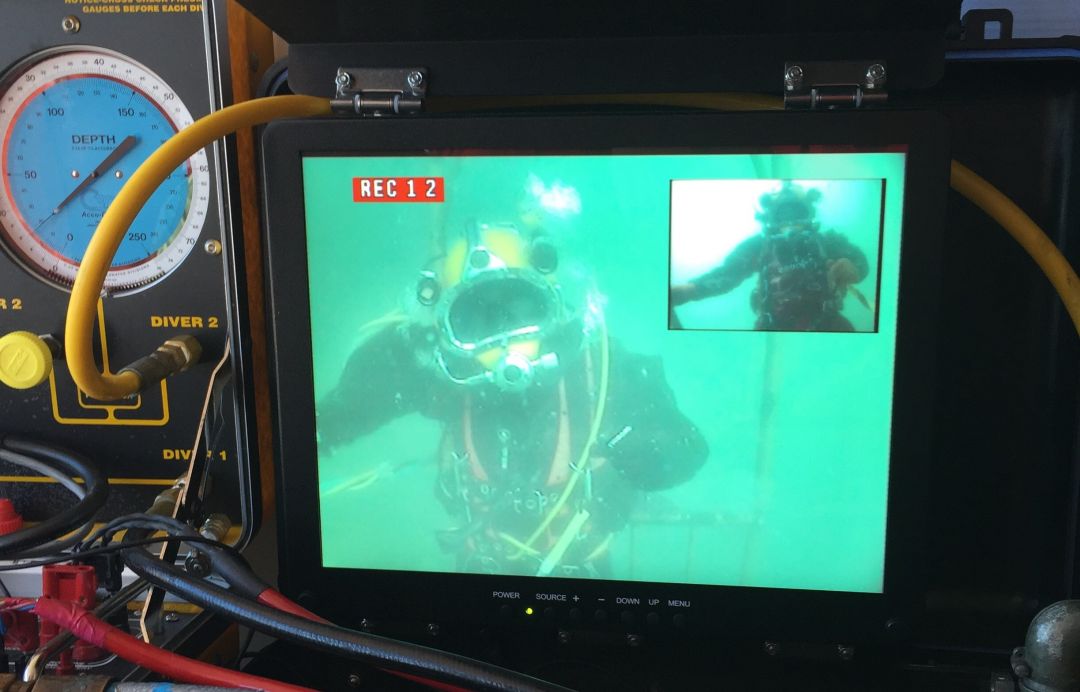

The marine terminal is controlled by radio from a distance of 9 km, and all the equipment and sensors that ensure its operation are powered by solar and wind energy.

Supplier of raw materials

Trading provides the three Rompetrol production units of the Group, Petromidia and Vega refineries and the sole petrochemicals division in Romania with crude oil and raw materials. The main source of crude supply is Kazakhstan, ensuring a stable and a reliable source of supply in a disruptive market.

It manages the petroleum products stocks in the refining and retail divisions in Romania and it also sells fuels and niche products locally and to the Group's subsidiaries (Rompetrol Bulgaria, Rompetrol Moldova, Rompetrol Georgia), as well as to the traditional partners.

Added Value Products

An important activity of trading is the selling of special products obtained at Vega refinery, the petrochemical products and LPG produced in Petromidia refinery.

White products of Vega refinery (naphtha, ecological solvents, n-hexane and white spirit) represent more than 60% of the total niche products sold by the trading division.

In recent years, Vega refinery processed record quantities of bitumen and of n-hexane due to the improved quality of the raw materials and an increase in the demand on the regional market.

The petrochemicals division continued to consolidate its market position by developing new sorts of polymers as well as by optimizing logistical operations for product sales.

The current needs of the medical sector created the context for our specialists to innovate and produce a special type of polypropylene dedicated to protective medical masks.

Larger quantities of LPG produced at Petromidia increased trading sales on the Romanian market and in neighboring countries such as Bulgaria, Moldova, Macedonia and Serbia, where there is a high demand.

Supply Chain

The strategic location of our main logistic assets in Midia Port, near Constanta allows the fast supply of crude oil to our refinery Petromidia through our own offshore marine terminal located 8.6 km out in Midia Port of the Black Sea.

At Petromidia refinery, the supply chain infrastructure consists in primary logistics (trains) that transport fuels to the six depots of our distribution companies in Romania (Arad, Craiova, Mogoşoaia, Simleul Silvaniei, Vatra Dornei and Zarnesti) or near abroad by secondary logistic (trucks) to the end consumers.

The onshore Midia Port terminals (Berth 9 A, B, C) allow shipping of oil products to our subsidiaries in Moldova, Georgia, Bulgaria, as well as to other traditional partners in the Black Sea region.

Automation Automation of the supply chain is in line with our digital transformation of our assets and it will have a significant impact in the overall efficiency of trading activities.

Another measure to consolidate and improve the supply chain activities in Romania is the modernization and automation of the fuel loading-unloading systems of the local depots and Petromidia refinery terminals.

The project was implemented in all depots in Romania and in our five terminals of the Petromidia refinery (loading platforms for railways, LPG loading).

Our logistic assets

Most of our logistic assets are located on the Romanian shore of the Black Sea, close to Petromidia refinery, the biggest unit in Romania and one of the most modern in SE Europe.

The company that operates these three main divisions is Midia Marine Terminal, established in 2007, by taking over the administration of the berths in Midia harbor from Rompetrol Logistics, a company that developed operations in this area since 2001.

- Offshore oil terminal and crude oil tank farm;

- Onshore oil and gas Midia Port terminals: Berths no. 1-4 and no 9 - 9A, 9B, 9C

- Petromidia and Vega Ramps

Unique project in Romania

Built in 2008, 8.6 km out in the Midia Port of the Black Sea, the crude oil terminal has a technical capacity of 24 million tons/year and receives vessels up to 160,000 tons deadweight.

The marine terminal transfers 5 million tons of crude, quantity operated by almost 50 tankers per year.

Through a pipeline system of over 10,000 meters (8,600 meters underwater and 1,500 meters on land), the crude oil is transferred directly to the 390,000 m3 capacity tank farm, also operated by Midia Marine Terminal.

Midia Marine Terminal has almost 250 employees, 48 of whom are specialized in operating the offshore terminal. More than 30 people are assigned to the onshore operations, carried out in the Midia Port, where MMT unloads and loads smaller vessels.

The largest share of MMT employees is in the Petromidia refinery, with over 100 people involved in the management of the loading/unloading ramps.

Midia Marine Terminal

Rompetrol owns and operates this state of the art offshore terminal in Midia Port since 2008, adding value to our downstream operations, by supplying with crude oil our refining activities. Midia Marine Terminal operates the oil terminal and the rest of the supply and storage systems of the Group.

Seven Berths in Midia Port and a rail and road infrastructure

Almost 550 vessels and 2 mill tons of oil products, LPG, ethylene & raw materials are imported and exported annually through the seven berths managed by the company in Midia Port.

- Berth 9 is the most modern and versatile terminal and the only cryogenic terminal in Black Sea. Having 3 terminals - 9A, 9B and 9C, it increased the transit of the finished products (for fuel products, ethylene and LPG) from Petromidia refinery up to 350.000 tons/month.

- Berths no. 1-4 (for crude oil & molasses).

The transfer via Petromidia and Vega refineries loading/unloading ramps exceed 3.5 million tons per year of fuel products & LPG, with 60.000 rail tanks operated and more than 35.000 truck tanks operated yearly.

Offshore services

Midia Marine Terminal has increased its naval fleet in 2015, currently operating three tugs -

- Tirreno, for assistance in handling 160,000 tdw of oil tankers;

- Bucharest and Astana, for hose maneuvers, offshore maintenance and works, diving support and assistance to vessels in the Midia harbor.

The fleet also includes a pilot boat and two working boats.

Ship-to-Ship operations in open seas

Byron Shipping is our second company specialized in offshore services, the only Romanian agency specialized in Ship-to-Ship operations in open seas, offering complete shipping services in all Romanian ports, Constanta and Midia included.

Operating initially as a shipping agency for the first oil tankers operated in Midia Port, it provides this kind of service to other relevant players in the Romanian Oil & Gas market.

The company is the interface of the ship owners with the Romanian authorities, ensuring a full range of specialized services for ships operating in seaports, such as Constanța and Midia, as well as in river ports.

The company equally contributes to the optimization of the traffic flow in Midia and Constanta Ports and also to efficient planning in the maritime terminals, in accordance with the needs and priorities of the Petromidia refinery and the petrochemicals division.